Multilayer wood (CLT) or Cross Laminated Timber, also known as “Xlam” and “solid timber”, as defined by the American National Standard, it is a prefabricated solid wood panel consisting of at least three orthogonal connected layers. In other words, it is a structural wood material that is laminated by gluing the longitudinal and transverse layers with structural adhesives to form a planar rectangular timber used for the ceiling, floor or wall applications.

In general, a CLT panel consists of a number of layers (3, 5, 7 or more) that it’s fibers are pressed perpendicular to each other and connected together with structural adhesives or typically mechanically with dowels or nails. Depending on the application, the direction of the outer layer may be different. Panels used as walls are generally designed to be longitudinally parallel to maximize the vertical burden capacity of the wall.

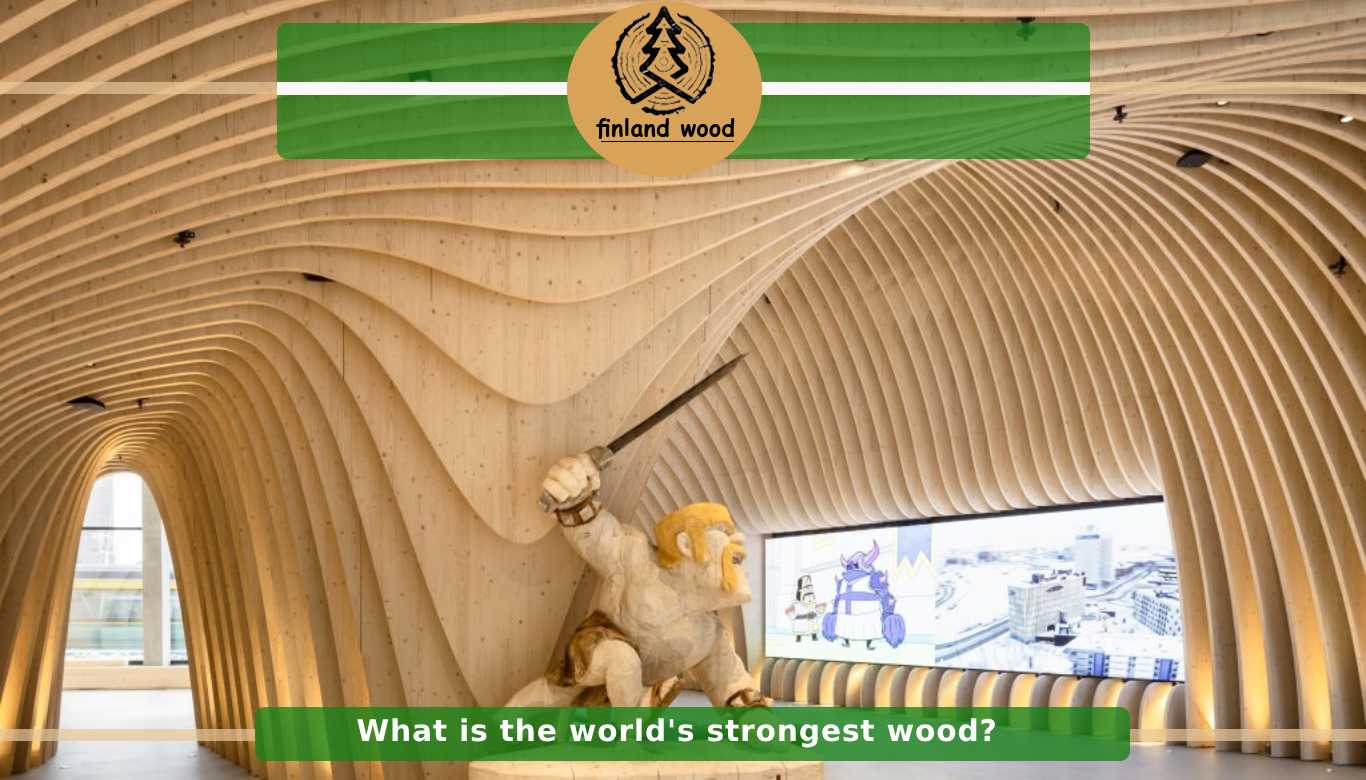

What is CLT – Cross Laminated Timber?

CLT multilayer wood technology is one of the products that is considered as the most important building material in the future. Timbers, which are formed by connecting together in perpendicular directions, provide many solutions at the same time due to their multi-directional high strength and the ability to produce with different types.

read more: Natural Wood Dining Table

Advantages of multilayer wood Cross Laminated Timber (CLT)

- sustainable consumption of primitive materials used for its production.

- An energy-efficient production process that makes the material environmentally friendly.

- Excellent static, mechanical and insulator properties.

- A style that makes the building structure incomparably lighter than other structures made of traditional materials.

- The possibility of producing prefabricated elements leads to the completion of the entire construction process in a short period of time. (The cost aspect is more effective)

- The possibility of combining with other building materials (steel, glass, plastic, etc.)

- Maximum freedom of architectural design.

Visual and quality

Multi-layer wood panels usually consist of three to seven layers. Normally there are an odd number of layers arranged symmetrically to the middle layer. Sizes vary depending on the manufacturer’s production areas and transportation conditions. Commercial companies offer standard dimensions of multilayer wood in lengths of 12 meters to 20 meters, in widths of 2.40 meters and 3.00 meters.

Woods, which can be produced in different layers, strengths and properties according to the desired static values, are used in columns, walls and floors. It complete projects in much shorter times, it does works with less cost and forces and with very little weight. timbers are a very logical solution from a safety point of view, because the light weight also minimizes the seismic force encountered in the event of an earthquake.

read more: wooden furniture

Fire resistant (Cross Laminated Timber)

Stable lamination provides excellent dimensions and gives the structure considerable strength with a very unique strength-to-weight ratio compared to other common structural materials.

CLT has unique structural properties that enable different and innovative projects and increase design flexibility. Due to wood’s inherent malleability and unique weight/strength ratio, it has many advantages over other traditional building materials such as concrete and steel.

Other benefits Cross Laminated Timber

From individual manufacturers to large construction companies, CLT structural systems are in place and ready to save time and money with a fast and accurate construction process.

CLT is a system based on large, lightweight panels that vary from manufacturer to manufacturer. Common widths are 60cm, 120cm, 240cm and 300cm. The length of the panel can be 18 meters or more and its thickness is 50 cm. Using fewer but larger elements means greater simplicity of construction.

One of the most attractive features of multilayer timber as a building system relates to the speed of construction of CLT buildings, substantially due to its prefabricated nature.

This leads to high precision, (pores in the panels are cut by using a CNC machine) faster completion, greater safety, less environmental destruction and less waste on site.

read more: Thermowood Facade

One study shows that CLT structures can be built at a speed that can be completed in as little as three to four days, compared to twenty-eight days per floor for a normal concrete structure. CLT panels can form an effective lateral burden resisting system. The researchers performed extensive seismic tests on CLT and found that they perform very well, especially in multi-floor applications, without permanent transmogrification. Multilayer wood panels are materials that require little or no insulator.

Since laminated wood panels can be produced to exact tolerances using CNC equipment, stronger panel connections provide better energy efficiency for the building. Solid panels also cause almost zero air permeation in the building. The internal temperature of a complete CLT(Cross Laminated Timber) structure can be maintained with only one third of the heating or cooling energy normally required.

Superior fire resistance is provided by CLT panels that have a thick surface. During conflagration, their mass burns slowly and eventually combustion stops in its structure. Because there is less free space in it, it cannot spread until the fire is detected.

Compared to concrete and steel structures, CLT structures are less damaged in a severe conflagration incident.

Application of CLT in different industries:

The distribution of forces is determined according to the thickness and strength of the wooden layers (8). When the CLT panel is used as a wall or floor, it resists versus axial burden (axial burden only) and bending burden. When used as a shear wall, it resists shear forces above the board (17). Thicker CLT panels provide greater resistance to bending and shear forces (18). Furthermore, since CLT transfers the burden it carries as a solid wall panel by spreading it over the ground, the dimensions of the foundation commensurate to it are reduced (17).

CLT can withstand both inside the board and outside the board forces as a result of the transverse structural arrangement (picture 6) (18). CLT(Cross Laminated Timber) has the capacity to pass through floor openings without intermediate carrier elements.

read more: How do you build a wooden porch awning

Structural and non-structural elements of the wall:

- Multi-floor structures with or without concrete foundation.

- Floor/ceiling, balcony wall and roof elements.

- Pre-insulated wall and ceiling cassette.

- balconies.

- Carrier columns.

- stairs.

Multilayer wood shows its potential to serve as an important structural element in the construction of buildings made entirely of wood.

CLT offers a wide range of advantages in terms of structure, environment, economy, functionality and architectural design. Timbers provide a conceptually sustainable and cost-effective solution that can compete significantly in the non-residential medium building market.

read more: Timber

Conclusion:

The advantages of timbers expand its range of applications from one-floor buildings to multi-floor residential buildings, multi-floor public buildings, industrial and commercial buildings, and even bridge structures. CLT(Cross Laminated Timber) wall panels have also been proven to be resistant to dynamic burdens by many tests performed in Europe, and multilayer wood is recognized as an earthquake-resistant material.

![Cross Laminated Timber [Stable And Strong Buildings With (CLT)]](https://finland-wood.com/wp-content/uploads/2022/09/CLT.jpg)